Facilities

Only by producing and growing your own raw materials can you control the quality and differentiation of your products with guarantees.Our main hallmark is our control and monitoring of the entire production chain of our products. We sustainably grow and produce our own raw materials. Improving the properties of the strains and researching how to improve and enhance their beneficial effects. This allows us to develop cultivation solutions with greater control over the quality of the active ingredients and to market unique solutions whose components are only grown and produced in our facilities.

New Agora Sabana Production and Experimentation Plant

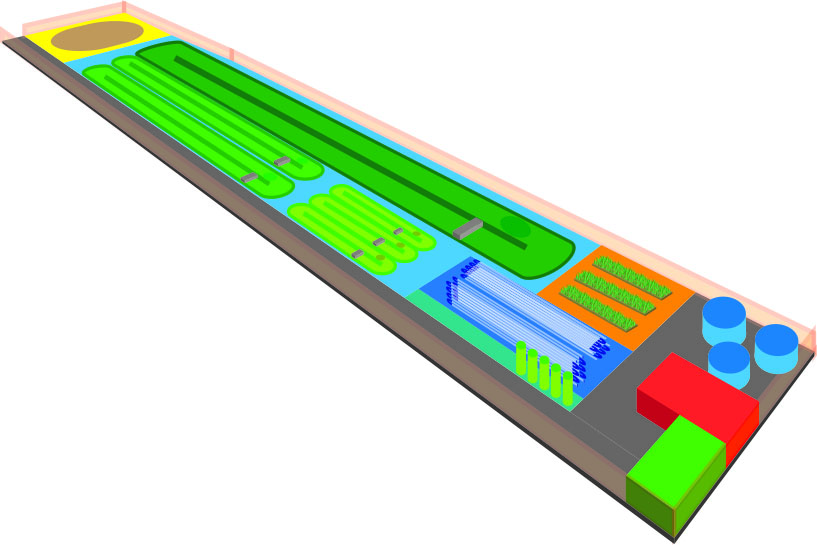

New Production and Experimentation Plant ‘Agora Sabana’.

Thanks to the great international acceptance of the natural biotechnological solutions produced by the company, BIORIZON BIOTECH is in the final stages of the expansion of its handling and packaging centre for natural products for agriculture, located in the Almeria Science and Technology Park (PITA).

Biorizon Biotech has built Europe's largest indoor microalgae and cyanobacteria cultivation plant dedicated entirely to the agricultural market.

The large-scale microalgae production plant contains different types of raceways, tubular photobioreactors and automated harvesting and homogenisation systems.

The plant is fully automated and monitored, as well as the preparation, harvesting and centrifugation of the culture media.

Expansion of handling and packaging centres for natural products for agriculture

Thanks to the great international acceptance of the natural biotechnological solutions produced by the company, BIORIZON BIOTECH is in the final stages of the expansion of its handling and packaging centre for natural products for agriculture, located in the Almeria Science and Technology Park (PITA).

The expansion of the facilities will mean an increase in the production capacity of the company, where we have found an expansion of the product portfolio portfolio as a result of the R&D developed, as well as an increase in international demand for them. The novelty of the products marketed by BIORIZON has exceeded market expectations, generating greater demand than the company's available capacity, making it necessary to expand the company's facilities, with the aim of continuing to lead in biotechnology applied to microalgae and bacteria for agriculture.

The extension of the company's facilities has received an incentive of 104,960.77 € from the Agency for Innovation and Development of Andalusia (IDEA) of the Andalusian Regional Government, 80% co-financed by the European Union through the European Regional Development Fund, ERDF, for the project ‘Extension of the Centre for Handling and Packaging of Natural Products for Agriculture’, with the aim of ‘Achieving a more competitive business fabric’.

BIORIZON products represent a sustainable alternative to the use of chemically synthesised plant nutrition and pest control products, making them a key solution and an example of applied research to improve the competitiveness of the agri-food sector. In addition to being non-polluting, the products have no safety period as they do not contain chemical residues, so that their application has a positive impact on food quality and safety.

Biorizon installs photovoltaic panels for self-consumption at its headquarters in Pita in order to minimise the impact of its activity.

BIORIZON BIOTECH has received a grant from the European Union from the European Regional Development Fund (ERDF) for the installation of photovoltaic self-consumption, within the Programme for the sustainable energy development of Andalusia in the period 2017-2020, which aims to achieve a cleaner and more sustainable economy.

Biorizon has started up an installation for photovoltaic self-consumption at its headquarters in the Science and Technology Park of Almeria (PITA). The project developed and implemented included the engineering design, supply, construction, commissioning and subsequent monitoring of a photovoltaic installation on the roof.

The electricity demand in Biorizon's production process in the facilities located in the Technology Park is mainly produced during daylight hours, which allows all the solar energy to be used and consumed during sunlight hours, without the need to resort to the electricity grid or minimise its use. This, in particular, will allow Biorizon to save more than 70% of the price of the energy consumed in the electricity bill, as well as ensuring greater economic efficiency.

The installation has 54 Mono-Perc technology solar modules of 440 Wp on a fixed roof structure, which will make it possible to generate clean energy all year round. In this way, Biorizon strengthens its commitment to the implementation of sustainable production systems through circular economy processes, minimising the impact of its activity on the environment.